Enhancing Productivity with Double Work Station CNC Tapping/Machining Centers #

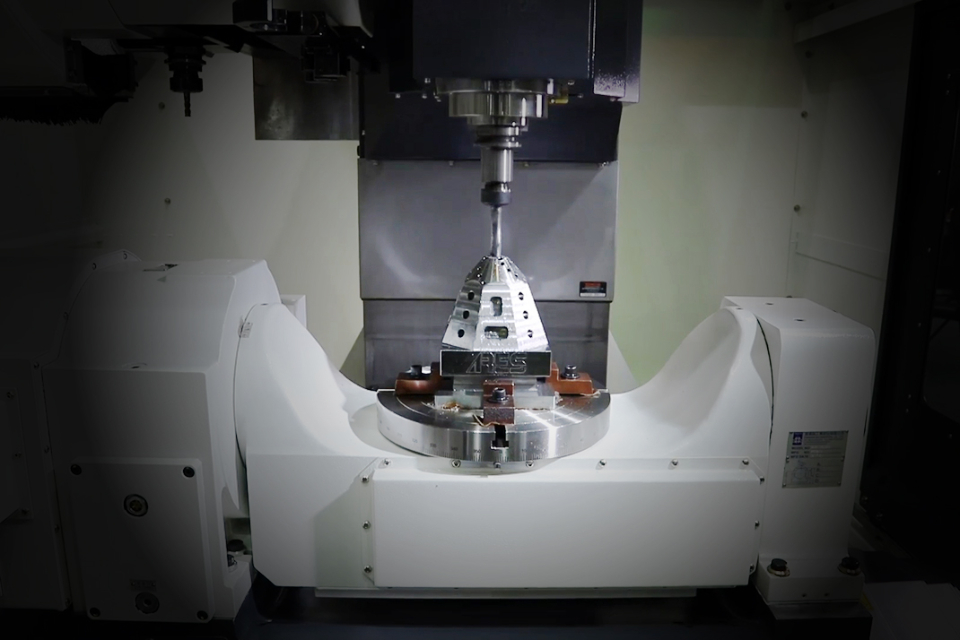

A double work station CNC tapping/machining center is engineered to deliver high-speed, high-precision drilling, tapping, and milling operations. Its innovative design features a full-travel column and a high-speed swing table (APC: Automatic Pallet Change), enabling the main working table to be divided and rotated for two separate work stations.

While machining is performed on the interior station, operators can simultaneously unload finished workpieces and load new raw materials on the exterior station. This setup eliminates downtime for workpiece changes, ensuring continuous machining and significantly boosting production efficiency. The swing table’s smooth rotation, without the need for lifting or lowering motions, enhances reliability and machining accuracy.

Key Advantages #

- The 5-axis configuration, combined with the double work station design, enables non-stop operations and maximizes machining efficiency.

- Pallet changes are simplified, either by pressing a button or issuing a command from the CNC controller.

- Human intervention and potential errors are minimized.

- A single operator can oversee multiple machines, especially during longer machining cycles.

- Suitable for both “high-mix, low-volume” and “high-volume, low-mix” manufacturing methods.

- Faster return on investment (ROI) is achievable due to increased productivity.

- Each work station can be optionally equipped with a CNC rotary table or a hydraulic/pneumatic system for automatic fixturing, further enhancing automation.

Versatile Applications #

Ares Seiki’s S-series double work station CNC tapping/machining centers are built for quality and versatility. They are widely used across various industries, including:

- Automotive parts manufacturing

- Bath-ware production

- 3C industries (computer, communication, and consumer electronics)

Featured Models #

For tailored solutions and further information, contact ARES MACHINERY.

S-3030

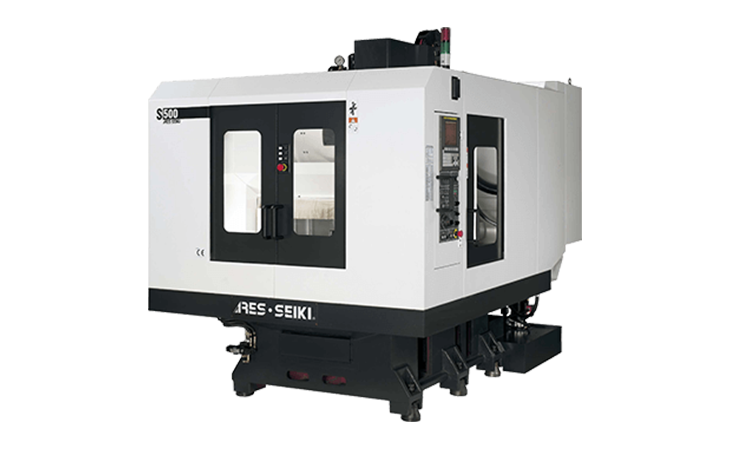

S-3030 S-500

S-500 S-6040

S-6040