Unlocking Precision and Flexibility with Five-Axis CNC Tapping Centers #

Five-axis CNC tapping machining centers represent a significant advancement over traditional three-axis systems. While three-axis machines operate along the X, Y, and Z linear axes, five-axis models introduce two additional rotational axes. This expanded range of motion allows the cutting tool to approach the workpiece from virtually any direction, greatly enhancing flexibility and precision.

What Sets Five-Axis CNC Tapping Machining Apart? #

Unlike conventional setups, five-axis CNC tapping centers can perform complex operations—such as milling, drilling, and tapping—on multiple surfaces of a workpiece in a single setup. This capability reduces the need for multiple fixtures and repositioning, streamlining the manufacturing process and minimizing production time. Industries that demand high precision and intricate geometries, such as aerospace, automotive, and medical device manufacturing, benefit greatly from these machines.

Key Advantages of Five-Axis CNC Tapping Machining #

- Complex Geometry Machining: The five-axis capability enables the creation of intricate features, including undercuts, deep cavities, and contoured surfaces—tasks that are challenging or impossible for three-axis machines.

- Reduced Setups and Increased Productivity: Machining multiple sides of a part in one setup minimizes the need for additional fixtures and repositioning, saving time and boosting efficiency.

- Enhanced Accuracy and Consistency: Fewer setups and part movements lead to improved part accuracy and repeatability, which is essential for industries where precision is critical.

- Superior Surface Finishes: Simultaneous movement across five axes allows for smoother, more precise cutting paths, resulting in better surface finishes and less need for secondary operations.

- Optimized Tool Life: Maintaining optimal tool orientation and contact angles throughout the process reduces tool wear and extends tool life, lowering operating costs.

High-Precision Machining for Diverse Industries #

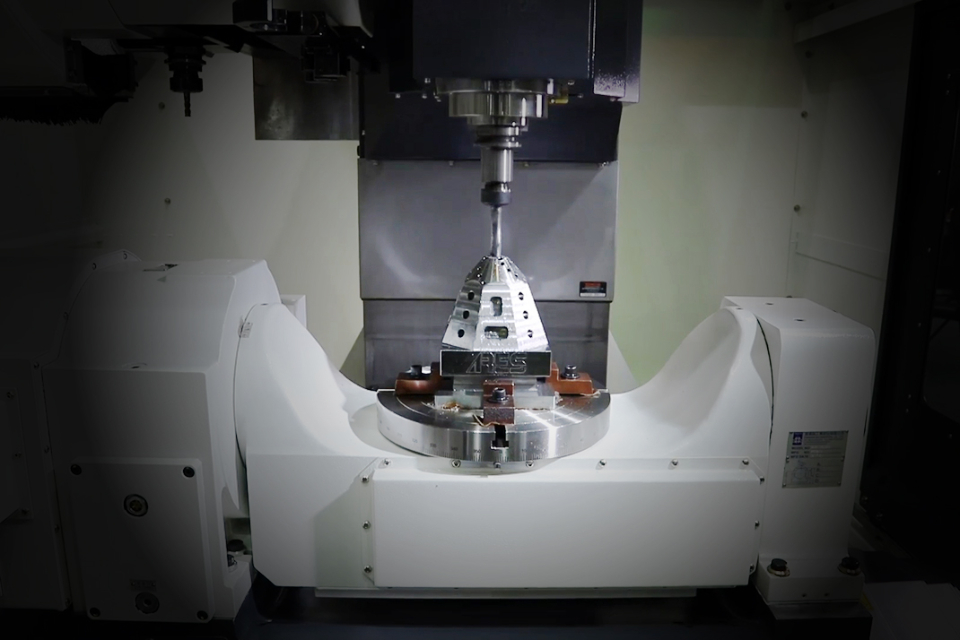

The Ares Seiki A5X Series five-axis CNC tapping machining center is engineered for sectors that require exceptional accuracy and efficiency. This advanced system can perform complex operations on multiple surfaces of a workpiece in a single setup and is compatible with a wide range of materials, including metals, plastics, and composites. Its versatility makes it suitable for aerospace, automotive, medical, and mold-making applications.

Featured Models #

Comparing 3-Axis and 5-Axis CNC Tapping Machining Centers #

3-Axis CNC Tapping Machining Center #

- Axes of Movement: Operates along three linear axes (X, Y, Z), allowing approach from three directions.

- Complexity of Operations: Best suited for simpler parts; complex geometries require multiple setups.

- Setup and Fixturing: Multiple fixtures and setups increase production time and labor costs.

- Surface Finish and Accuracy: Limited to linear movement, which can result in less optimal surface finishes and lower accuracy for complex parts.

- Applications: Commonly used for parts with straightforward geometries and in industries where ultra-high precision is not essential.

5-Axis CNC Tapping Machining Center #

- Axes of Movement: Moves along three linear axes (X, Y, Z) and two rotational axes (A, C), enabling approach from any direction.

- Complexity of Operations: Ideal for complex, multi-faceted parts; can perform intricate operations in a single setup.

- Setup and Fixturing: Fewer setups are required, reducing setup time and labor costs.

- Surface Finish and Accuracy: Allows for smoother cutting paths and better tool positioning, resulting in superior surface finishes and higher accuracy.

- Applications: Essential for high-precision industries such as aerospace, medical, and automotive, especially where complex geometries and superior accuracy are required.

Learn More or Get in Touch #

For tailored solutions in CNC tapping and machining, contact ARES MACHINERY for expert guidance and support.

A5X403

A5X403 A5X404

A5X404