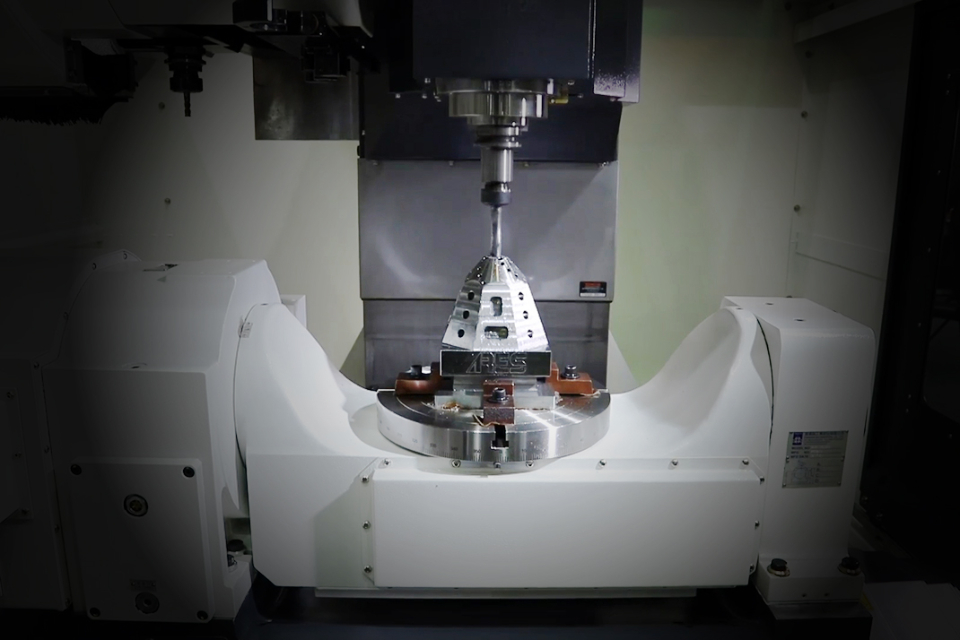

Horizontal Machining Centers: Precision, Efficiency, and Versatility in Modern Manufacturing #

CNC horizontal machining centers (HMCs) are essential tools in advanced manufacturing, recognized for their horizontal spindle orientation parallel to the ground. This design not only enables high-precision milling of metal workpieces but also ensures efficient chip evacuation, as metal chips naturally fall away from the workpiece and cutting tools. This feature reduces the risk of chip accumulation, which can otherwise affect machining quality and tool longevity.

Key Features and Advantages #

-

Streamlined Setup and User-Friendly Operation

The H Series CNC horizontal machining centers are engineered to simplify setup procedures. With an intuitive interface and automated features, these machines reduce setup complexity, minimize errors, and boost productivity. Even operators with less experience can confidently manage high-value tasks. -

Automated Chip Management

Equipped with a chip conveyor system, these machining centers automatically transport chips out of the machine. This eliminates the need for manual chip removal, saving both time and labor costs, while also reducing safety hazards associated with chip buildup during cutting cycles. -

Enhanced Surface Finish and Tool Life

Effective chip removal prevents chips from being re-cut, resulting in superior surface finishes and improved workpiece accuracy. This also extends the lifespan of cutting tools by minimizing wear and tear, leading to significant savings on tooling expenses. -

Rotary B-Axis for Multi-Sided Machining

The inclusion of a rotary B-axis allows for machining on three sides of a workpiece within a single cycle. This capability enhances machining accuracy, reduces the need for repositioning, and minimizes secondary operations, ensuring consistent, high-quality results. -

Dual Working Stations and Automatic Pallet Changer (APC)

Featuring dual working station tables and an automatic pallet changing system, these centers support continuous, non-stop operations. While one workpiece is being machined, another can be set up on the alternate station, minimizing downtime and maximizing throughput.

Applications Across Industries #

ARES Machinery’s H Series horizontal machining centers are built for high speed, accuracy, and efficiency, making them suitable for a wide range of industries, including:

- Auto parts manufacturing

- Bath-ware production

- 3C products (computer, communication, and consumer electronics)

- Aviation industry

H Series Product Lineup #

Explore the H Series horizontal machining centers, each designed to meet diverse production needs:

For tailored solutions and further information, contact ARES Machinery.

H4030

H4030 HD403-5X

HD403-5X H4040

H4040 H4040P

H4040P HM4040

HM4040 HM4040P

HM4040P