Advanced Machining for Bathroom Hardware Components #

In the bathroom hardware industry, the demand for components that combine both functionality and visual appeal is ever-increasing. Ares Seiki addresses these needs by providing high-precision, high-efficiency CNC machining equipment tailored for the production of faucets, valves, and other essential bathroom hardware parts.

Applications in Bathroom Hardware #

Our CNC solutions are utilized in the manufacturing of a wide range of components, including:

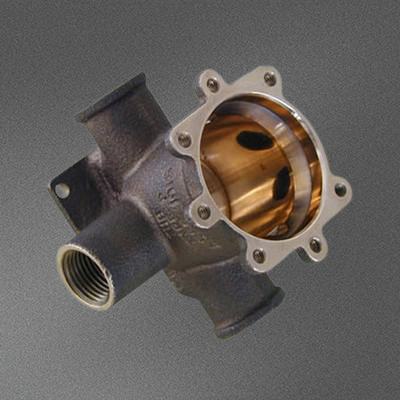

- Faucet valve bodies

- Distribution heads for air conditioners

- Compressor valve bodies

- Flow control valves

- Door closers

- Spray gun bodies

- Copper electrodes and molds

- Nail guns and nail pullers

These applications require strict adherence to dimensional accuracy, surface finish, and durability standards, ensuring that each product meets market expectations for both performance and aesthetics.

Related CNC Machining Solutions #

Ares Seiki offers a comprehensive lineup of CNC machining centers designed to optimize production in the bathroom hardware sector:

- CNC Tapping Center - A Series

- CNC Tapping Center - R Series

- 5 Axes Tapping Center

- 5 Face CNC Vertical Machining Center

- Long Table CNC Tapping Center

- Double Stations Tapping Machining Center

- CNC Horizontal Machining Center

Each solution is engineered to deliver consistent results, supporting manufacturers in achieving high throughput while maintaining quality standards.

Workpiece Gallery #

Support and Contact #

Ares Seiki is committed to providing tailored solutions for your machining needs. For further information or to discuss your specific requirements, please contact us.